GLARE CONTROL FABRICS

The prevention of glare is one of the most important functions of an internal shading solution. Clearly, glare can have a major impact on our ability to work with a computer screen in the office or read digital boards in a class room. When occupants experience glare, their ability to do their job plummets dramatically.Glare control is best achieved by roller blind fabrics having an openness of less than 5% and consist of opaque yarns or are metallised on one side. Read below why.

Overview

Glare – A manageable annoyance

What is glare?

Glare can occur when the amount of light on the eye is too high or when there are contrasts in the field of view that are too extreme. Often, both situations occur simultaneously. In an office, this can easily happen when there’s direct sun on the façade. Research showed that the total amount of light at the eye (illuminance or lux-value) is the strongest predictor of glare. If this value exceeds 3000 lux, most office workers will experience severe glare.

How to control glare

Clearly, glare can be controlled by reducing the amount of light entering through the windows. The effectiveness of doing this depends on how much of this reduced light flow is directly transmitted and how much is diffusely transmitted. Ultimate glare control is achieved by black out fabrics. In most cases, this is not the level of control needed.

EN 14501

The European norm EN 14501 gives a practical framework for quantifying glare control. In EN 14501, the ability to control glare is classified on a scale of 0 to 4, where 0 indicates very little effect and 4 indicates a very good effect.

In general, we recommend fabrics having glare control class 2 or 3. These are fabrics that have an openness of less than 5% and do not allow more than 4% of the light to pass through the yarns. These fabrics will provide adequate glare control for occupants viewing parallel to the window.

Best fabrics to control glare

| Serge 1% OF and 3% OF - Grey-White | Grey-Sand | Grey | Grey-Black | Black | |

|

A closer look at glare

The fish eye photographs below show the effectiveness of a screen fabric in controlling glare.

Without Screen Fabric

With Screen Fabric

Luminance

Luminance

EN 14501

EN 14501

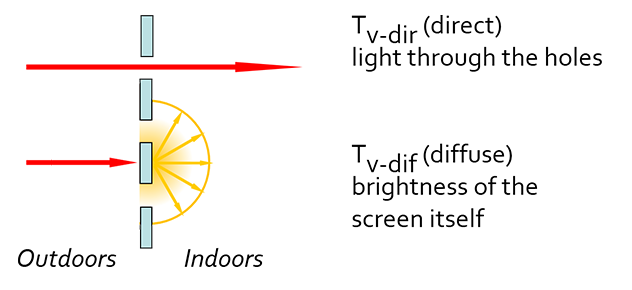

The European norm EN 14501 provides a very practical framework that relates direct and diffuse transmittance of screen fabrics to their ability to control glare.

Direct transmittance occurs through the holes in the fabric and determines how much solar radiation goes directly through the screen. The well-known openness factor is a proxy for the direct transmittance.

Diffuse transmittance is transmittance through the yarns of the fabric. The diffuse transmittance determines the brightness of the screen itself when illuminated from the outside. When too high, the screen itself may become a source of brightness and glare - as in the picture below.

When directly lit by the sun, the screen becomes a bright source of light of about 7000 cd/m2, more than 20 to 30 times brighter than a computer screen.

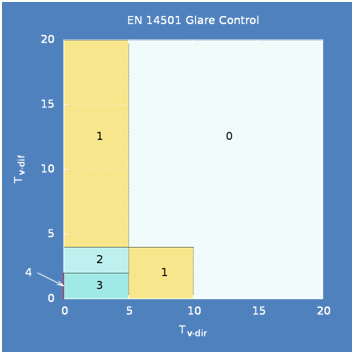

The EN 14501 glare control classes are most easily represented in a two dimensional graph of direct and diffuse transmittance. A particular fabric is represented by a point in this plane. The ability to control glare is classified on a scale of 0 to 4, where 0 indicates very little effect and 4 indicates a very good effect.

"Good effect" is achieved by fabrics having direct transmittance less than 5% and diffuse transmittance below 2% (Glare control class 3). Only fabrics with no direct transmittance (no openness and view through) and a diffuse transmittance less than 2% achieve a glare rating of 4 – "very good effect." These are black-out or very dark dim-out fabrics. Except for presentation rooms, this is normally not the sort of light control that is needed in an office.

Fabrics attaining a glare 3 rating will either have dark yarns or be metalized. Only these characteristics can guarantee less than 2% diffuse transmittance.

View direction

View direction matters a lot. In offices and class rooms the view direction of occupants is ideally parallel to the window. If an occupant directly faces a window with the sun in the central field of view, glare protection using class 2 or 3 fabrics will generally not be adequate.