Richard E. Lindner Center U. of Cinn.

Location:

Cincinnati, OH, United States

Architect/Specifier:

Bernard Tschumi; glaserworks; Eva Maddox

Featured Products:

Overzicht plafondsWhen faced with a challenge, Bernard Tschumi relies on conceptual power. For a multipurpose athletics facility in the University of Cincinnati's tightly packed "Varsity Village," the architect chose a most intriguing site, though perhaps the most difficult. The big idea: Squeezed into a sort of boomerang shape by existing fields, a stadium, recreation center and an arena, the new building could capture the residual space as a hub of campus athletics.

Then came concept two. To enhance its functionality and animation as a central terminal, Tschumi envisioned a full-height atrium running through the doglegged floor plan. To create this form-and to span an existing mechanical area that had to be column-free -- the architect conceived of a steel diagrid frame, effectively producing a five-story truss. Outside, the concept generated a memorable curved façade of precast-clad triangular cutouts. Inside, it produced a grand space that knits neighboring sports facilities together. Despite its unlikely shape and siting, the building contains a cathedral-like space -- a veritable shrine to the UC Bearcats.

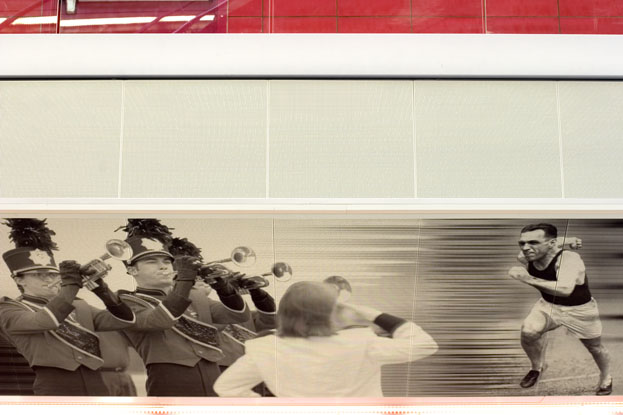

Overhead there's a third signature move. Seizing on this dramatic interior, Tschumi worked with designer Eva Maddox to create an installation called "Heritage Hall" showcasing the university's achievements. Sepia-toned graphic murals are emblazoned onto Luxalon® metal ceilings by Hunter Douglas. The flatness and flush joints of the system keep the photographs looking continuous and clean. The perforated planks also enhance the acoustical performance in the reverberant space. The only echoes of the murals -- made of up to 95% recycled material -- are the matching graphics on glass office partitions below.

According to creative director Brian Weatherford of Perkins+Will Eva Maddox Branded Environments, the graphics were applied directly to the ceiling panels by means of a digital printing press. "It's a flatbed printer that can accept material up to two inches thick